Generating Nuclear Energy

About Nuclear Energy

The generation of nuclear energy produces no greenhouse gases or air emissions. Together with renewable energy options, nuclear energy is critical to meeting our environmental and energy goals.

Affordable Energy

Since 2001, nuclear plants have achieved the lowest production costs between coal, natural gas and oil. Fuel costs account for 31% of the overall production costs of nuclear plants. Fuel costs for coal, natural gas and oil, however, account for more than 75% of the production costs.

Safe Energy

The lost-time accident rate at nuclear plants is among the lowest in the nation at .3% compared to 2.4% for the manufacturing sector. Power plants use steam-driven turbines to generate most electricity. Nuclear plants make steam using the heat produced by splitting atoms. Atomic particles called neutrons strike each other, splitting atoms into fragments. These fragments strike other atoms, releasing energy.

How it Works

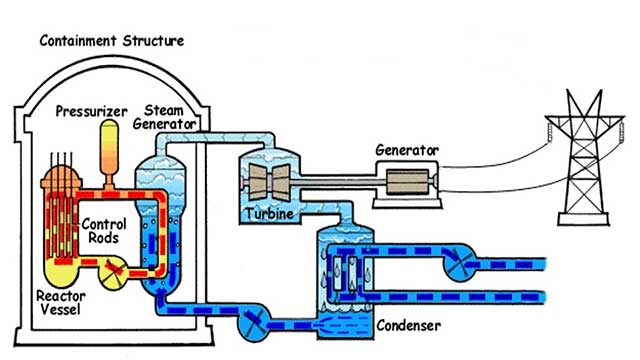

The heat produced by the splitting (fissioning) of uranium atoms turns water into steam. The steam pressure spins a series of windmill-like devices called turbines, which are connected to an electric generator that produces electricity. Using the diagram below as a reference, here in more detail is how the process works at Callaway Energy Center:

When an atom splits, or “fissions,” it releases energy in the form of heat. It also releases neutrons, which go on to fission other atoms, creating more heat and releasing more neutrons. This continuing activity is called a nuclear chain reaction.

Inside the nuclear reactor vessel, the controlled fissioning of uranium atoms heats water that is pumped through the reactor. Although this water reaches an average temperature of 588 degrees Fahrenheit (309 degrees Celsius), it doesn’t boil, because it is kept under high pressure (2,235 p.s.i.g.). This hot water from the reactor vessel is pumped through four large heat exchangers called steam generators (only one is shown in the diagram) where the heat is transferred to a second, separate water system.

The water in the second (secondary) system is under less pressure, so the heat causes it to turn to steam. This steam then flows to the turbines. Meanwhile, the water in the first (primary) system returns to the reactor vessel to be reheated and repeat the process.

When the steam reaches the turbines, the steam pressure against the turbine blades causes the turbine shaft to spin. Attached to the shaft is a rotor that turns inside the generator. The turning motion of the rotor - a large electromagnet - inside the stationary coils of wire (stator) of the generator produces electricity.

This electricity is then boosted in voltage by a transformer and carried from the plant on high-voltage lines that connect to the Ameren transmission system.

After the steam in the secondary system passes through the turbine blades, it goes into the condensers, located below the turbines, where it passes over thousands of tubes carrying cooling water from the cooling tower. This cooling water absorbs heat from the steam, causing the steam to condense back into water, which is then pumped back to the steam generators to be reheated and start the steam cycle over.

The cooling water from the condensers flows back out to the cooling tower where the heat it has removed from the steam is released to the air. Except for some water lost out the top of the cooling tower through evaporation, most returns to the condensers again to repeat the cooling process. The water lost through evaporation is replaced with water from the Missouri River.